Orhan GÜRSEL Project Consultant; INTEGRATION OF MES SYSTEM WITH INJECT PRINTER IN CABLE INDUSTRY

In the cable industry, texts with product specifications and special codes are printed on the sheath at the production site. This writing process is done by inject printers while the production continues. This process is of high importance, as it also specifies the characteristics and standards of the cable. The spec information that comes with the work order is written manually by the operators and this process takes about 15-20 minutes for each work order.

An average of 750 minutes will be spent for this process in a factory where an average of 50 work orders are opened per day. When incorrect inject coding occurs by the operator; time, raw material and labor costs will be incurred.

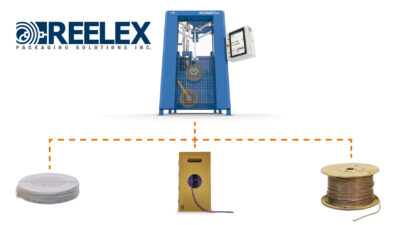

The trexDCAS MES system communicates with your inject printers in your field and transmits the spec code entered by the engineering office to the inject printers without operator intervention, and ensures that the process is error-free.

The most important of the problems that will occur when this process is done manually; It is to pay the fee for sending the wrong product to the customer after an incorrect injekt letter and to rework. For example, when the produced 50,000 meters of cable is received as a return from a customer located in another country; To correct this process, the sheath of the cable is stripped by reworking. Since this process cannot be as fast as in the production process, it creates an extra workload and personnel expense. In addition to the lost time, the plastic raw material spent for the sheath is also returned to the company as an extra expense. Since the deadline is exceeded and the cable is re-sheathed, the current work plan is divided and a work order is received. Since problems such as late delivery of the products of other customers may occur with the change of the planning, the wrong coding of a spec text in the injection or the application of the wrong color will cause the company to experience serious financial losses.

In addition, the time lost before each work order will return to the company as a lost time in which no production can be made. Thanks to the trexDCAS injekt printer integration, job loading time is minimized and the possibility of writing incorrect spec code is eliminated. Maximum gain is achieved with a single parameter.