Rod Wire Drawing – Highly Efficient And Highly Qualitative

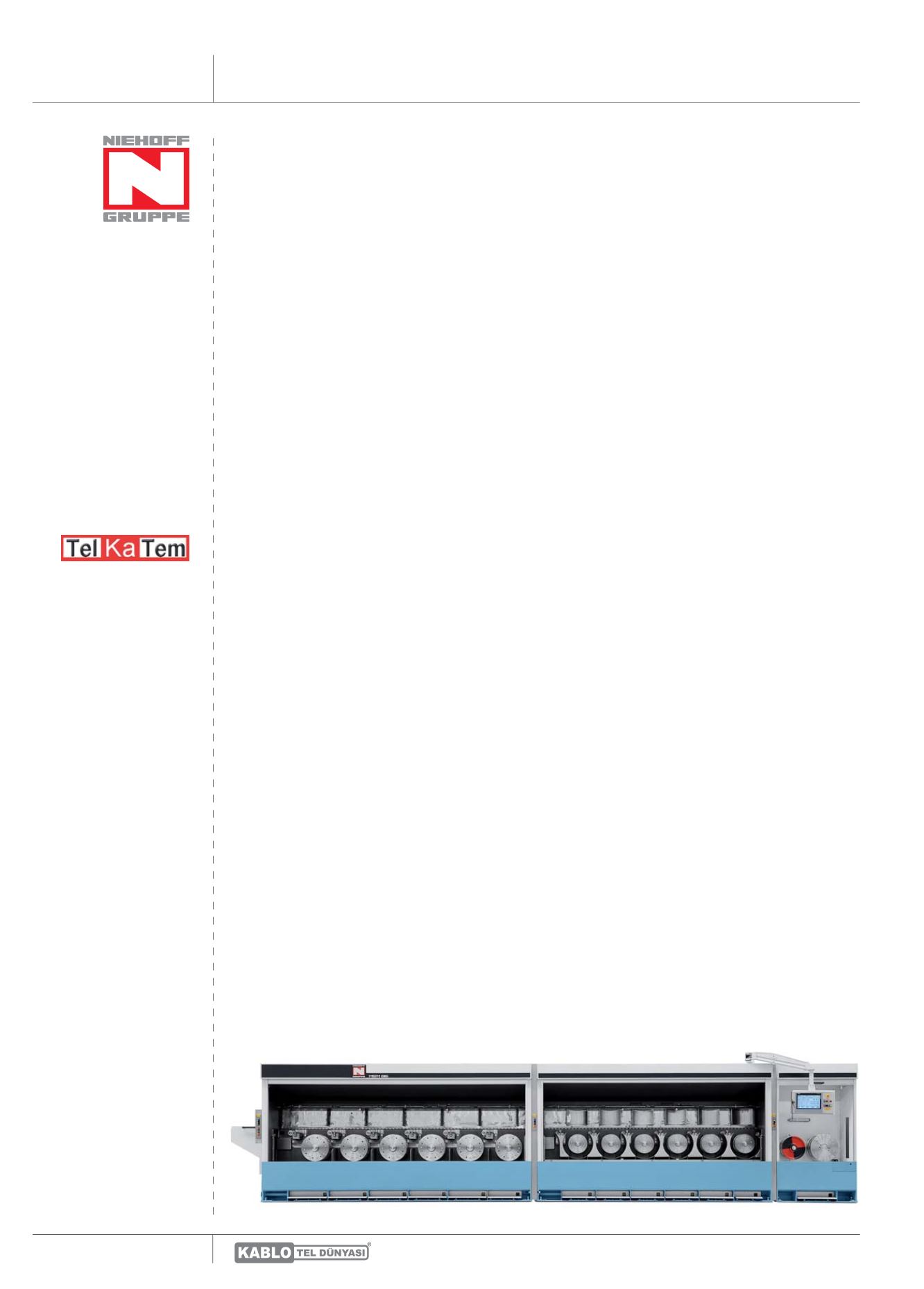

The rod breakdown machine type MSM 86 from Niehoff

Today, energy efficiency is a buzzword everywhere, also in the wire and cable industry when it comes to investments.

Maschinenfabrik Niehoff proves with each new machine generation that their innovative further developments are tech-

nologically always one step ahead.

Rod Wire Drawing Technology

For many years the wire and cable industry has been benefiting from the groundbreaking impulses and new standards

which Niehoff has been setting again and again. For instance, the rod breakdown machine type M 85 has become the

worldwide top-selling rod breakdown machine for non ferrous wires. Niehoff launched it in 1962 and has continuously

further developed it since then. In 1998 the individually driven rod breakdown machine type MSM 85 was used in an

industrial application for the first time. The current result of the development work by Niehoff in this field is the rod bre-

akdown machine type MSM 86. Designed for wires made of copper, copper alloys, aluminum, aluminum alloys and other

non-ferrous metals, the machine can be combined with a continuous annealer of the R 502, RA 501 or RI 420 types,

which are extremely powerful and work with high energy efficiency. Modular design and criteria such as the number of

drafts, the drawing capstan diameter and the final capstan modules enable the MSM 86 to be adapted ideally to indivi-

dual customer requirements.

Design Refinements

One of the characteristics of this machine is a special mechanical sealing system which reliably separates drawing emul-

sion and gear oil. Characteristic are also the drawing die holders with an innovative pressure lubrication and cooling. An

increased productivity is achieved thanks to the quick drawing die change system which reduces downtime when chan-

ging the machine setup for different dimensions.

Energy Efficient

As slip is minimized, capstans which are not in use can be switched off and the motors of the small capstans in the wire

outlet section are directly coupled, energy consumption is reduced to a minimum: in comparison with the predecessor

model MSM 85 energy savings of up to 10 % and in comparison with conventional rod breakdown machines even of up

to 20 % in total are achieved.

Easy to Operate

The machine is simple and intuitive to operate by means of a touchscreen with a network-compatible NMI (NIEHOFF

Machine Interface) color interface. The NMI displays the production parameters, gives maintenance instructions and

offers diagnostic functions. Data can be recorded and archived, and a recipe data management completes the range of

functions. With the NDI (NIEHOFF Data Interface) process related data and machine data can be exported or imported

via Ethernet and OPC server to an MES/ERP system.

The Result: High Wire Quality

The electronic control allows operation with minimized slip. This concept together with the optimized wire path, the

pressure lubrication and cooling of the drawing die holders and the optimum cooling conditions in the fully submerged

drawing basin finally has one result: the high quality wire surface of a wire drawn on an MSM 86.

Technical Data MSM 86

two-wire version*

max. production speed 40 m/s

max. production output 48.000 t/a

(for 7.000 hrs operation and 85% utilization, wire product 2 x 2,60 mm)

max. inlet diameter 2 x 8,00 mm

finished wire diameter 2 x 1,20 – 2 x 3,80 mm or 1 x 1,20 – 1 x 5,50 mm

*For copper with an inlet strength of 250 N/mm

2

Complete Solutions From a Single Source

Maschinenfabrik Niehoff develops and builds with an experience of more than 60 years all machinery needed for the

production of non-ferrous metals wires and the further processing into automotive, data and special cables, with the

exception of extruders. In addition, the portfolio contains technical assistance by professional specialists who speak

the customers´ languages. The reliable supply with original Niehoff wear parts and spare parts, machinery inspection,

refurbishment and maintenance measures as well as machine operator and maintenance training courses complete the

range of services. Niehoff Group offers custom-tailored solutions from development and planning to turnkey projects of

complete cable factories.

Fig. Niehoff’s rod breakdown machine type MSM 86 offers a high degree of energy efficiency and wire quality

Expertise, Customer Driven, Service – In Good Hands with NIEHOFF

Maschinenfabrik

Niehoff GmbH

Co.KGWalter-Niehoff-Straße 2,

91126 Schwabach

Germany

T.:

+49 (9122) 9770

F.:

+49 (9122) 977155

info@

niehoff

.de

www.

niehoff

.de

Kaya Sultan Sokak

No:83 K:6 34742 Kozyatağı

İstanbul/Türkiye

T.:

+90 216 372 69 26

F.:

+90 216 372 69 32

info@

telkatem

.com.trwww.

telkatem

.com.trTürkiye Temsilcisi

/ Agent in Turkey

2017-2018

KABLO YAN SANAYİ REHBERİ

CABLE INDUSTRY GUIDE

www.

kabloteldunyasi

.com

10