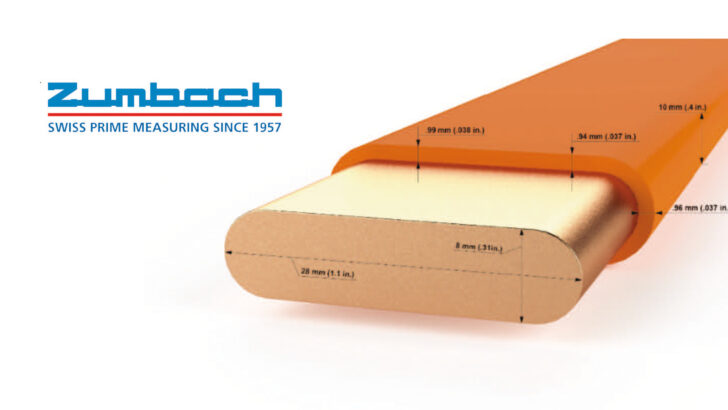

ZUMBACH In-line Quality and Process Control for Busbar and Flat Conductor Applications

Measurement of wall thicknesses, geometries and dimensions

Producing insulated flat copper and aluminum wires, cables or bars is highly complex and requires a sophisticated knowledge within the extrusion business. Corresponding measuring tools for monitoring the process and getting the quality under control are the basis for performing on the highest level of production capability.

Zumbach solutions and benefits

With many years of experience in the field of various measuring technologies, Zumbach offers tailor-made solutions for the continuous measurement and monitoring of non-round products, covering dimensional, geometric and wall thickness measurement, insulation fault testing, length and speed monitoring as well as process control.

Wall thickness measurement

Critical to the performance of a conductor is the uniform alignment of the wall thickness centrally around the circumference of a profile. On non-round products the additional challenge for maintaining control is that first it is necessary to accurately measure the wall thickness around the circumference.

By using proven UMAC® ultrasonic measuring technology and by offering customized transducer holders to meet customers need, Zumbach are able to offer holders specifically tailored to insulated flat products. Providing 4, 6 or even more measuring point solutions (to achieve maximum measurement coverage) precise information about the positioning of the conductor bar within the insulation itself is provided in real-time.

UMAC*

Measurement of wall thicknesses around the perimeter of the flat bars Holders with 4, 6 or more measuring points available Continuous monitoring and trend analysis Proven ultrasonic measuring principle

Other important parameters

Outside dimensions, profile geometry, insulation defects and length are also important process and quality parameters. Zumbach offers a range of quality monitoring solutions for extrusion measurement and process control including:

ODAC® XY with oscillating device DVW / DVO for measuring the outer dimension

PROFILEMASTER PMM Series non-contact measurement of outer dimension and geometry

Sparktester high voltage insulation fault detector

LSV speed and length sensors

USYS processor, acquisition and display system