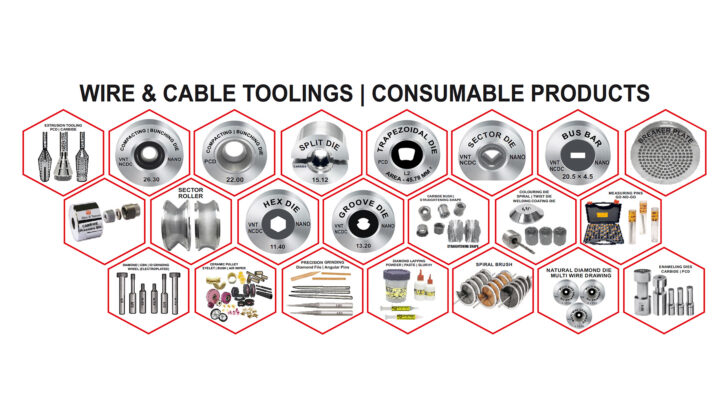

Ajex & Turner: An initiative approach to design TW | Sector Conductor Dies to draw aluminium & copper strands that will meet exacting ASTM Standards

J.S. Gupta

Founder & CEO

India Based Ajex & Turner Wire Technologies is a global leader in wire and cable industries since 1962. TW | Sector Conductor Dies in PCD | VNTNano | Carbide to draw aluminum strands to produce ASTM Standards | ACSR | ACCC | AMSTERDAM | CASABLANCA | ECO PANTHER | ECO DOG | ACSS-FALCOL Conductor |ACFR122 | ACFR ROSEWOOD | ACSS Apple | ACCC Hamburg | Copenhagen & many others as per ASTM Standards approved by most of the power grid Corporations throughout the world. A press release said that the company’s TW dies are designed to ensure accurate quality parameters to obtain aluminum strands that are shaped to provide a smooth outer surface that can meet applicable ASTM standards. The dies are made from high-quality raw materials that enable them to be both efficient as well as long lasting. The drawing shows an example of TW shaped compacting.

High quality raw materials VNTNano | PCD | Carbide are used for making our TW dies efficient and long lasting. To resolve the issue of smaller diameter conductor, Ajex & Turner’s trapezoidal-shape dies can be enlarged to provide a greater cross- sectional area of aluminum and match the diameter of the conventional round conductor.

Regarding the production of dies and Extrusion Toolings, we use artificial intelligence to calculate the hot and cold majoring values. There by we take into account the shrinkage of Toolings and are able to predict already at the beginning how the final product will look like this is important for our customer to produce high quality the products right from the beginning.

We can manufacture the Trapezoid Die. If you have a drawing and a technical data sheet for the Trapezoid, please send them to us. This will allow us to create a design and provide you with an offer.

The Process involves two steps :

• The standard process where we create the Trapezoid shape using an RBD machine

• The second process involves using a standing machine to bunch layers of Trapezoid wire.