Metal eyeglass frames with elegant and clear contours-Photo: by JHRS; Seamless curvature for eyeglasses Modernization of high-precision 3D eyeglass frame bending machine from Baumüller and Schüssler Technik

High-precision special machines of Schüssler Technik company, leader of the market, ensures production of modern eyeglass frames in a simple way for eyeglasses with different shapes and materials. The company also offers creative design alternatives for eyeglass producers throughout the world.

Oval, angular or round or a plain gray or a vivid pink design…

There are almost no limitations in terms of creativity in production which is a decisive factor in purchasing eyeglasses frames. However, appearance is determined not only by shape and color, but also by the type of material. Eyeglass frames produced from various metals such as stainless steel, new silver, phosphor bronze and titanium are dominating the fashion industry since several years. Schissler Technik, operating in Pforzheim, Baden Württemberg is specialized in this field. This midsize company manufactures quality machines for production of eyeglass frames since more than 50 years in the sector. The company additionally manufactures metal wire profiles in which glasses will be placed subsequently in addition to machines for bending the eyeglasses frames. Millions of different spectacle frames of numerous large eyeglass frame production companies are manufactured in a simple and precise way by virtue of the foregoing machines of the company..

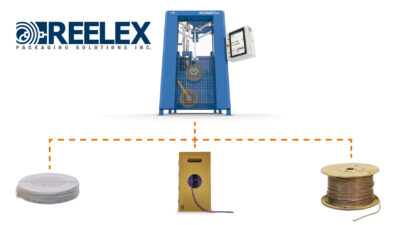

Operation principle of S-514 3D eyeglass frame bending machine The new CNC 3D eyeglass frame bending machine S-514 produces eyeglasses frames from various metal profile wires such as stainless steel or titanium, with different material thicknesses. The product output of the eyeglass frames per hour is up to 1.350 pieces. All known alloys can be utilized for eyeglass frames up to 2.5 mm in width and 2.5 mm in height. Baumuller’s precise drive and automation components adjusted in an ideal manner to each other are relied on as an outstanding feature of the eyeglass frames, which are manufactured with high accuracy.

Programming of the machines is carried out by copying of data (DFX or several form data of the Schüssler Technik) via USB or over the network or by copying of a molder at the same time. The user is able to set parameters such as bending, correction values and steel wire thickness on the touch screen directly. The eyeglass frame gets the desired curvature radius in other words the basic curvature (primary curvature) by virtue of shaped bending. The operation of the machine allows the wire to be adjusted in such a way that even when the wire is bent extraordinarily (e.g. like in sports glasses), the nut can come in a perpendicular way to the middle axis. In this way, the eyeglass can be securely attached to the frame subsequently. Production without loss

One of the great advantages offered through S-514 is the ability of performing segment corrections.

This means that form of the eyeglass frame can be divided into several segments until the bent spectacle can provide quality requirements both in the 2D form and inthe primary curvature frame which then can be corrected. Particularly in the critical range of eye types and wire profiles this is an extremely helpful feature. Another added value of the machine is its operation without any loss at all. In this way, the eyeglass frame can be produced without the waste of high quality profile wires such as gold or titan after each bending operation are used directly in the next eyeglass frame.

The electronics parts and seven drives are all located in a narrow space in the switch cabinet thanks to the machine’s space-saving design and the compact components of the Baumüller. Four bending axles ensure three-dimensional bending and three control axles ensure the separation of wires. Axle drives provide high quality in bending and requires no maintenance.

How does the 3D eyeglass frame bending machine operate?

The four bending axles produce the 3D eyeglass frame which is parallel to the intermediate line:

• Sending coils

• Bending wire

• Shape curvature (primary curvature)

• Subsequently counter rotation where the glass will be cut for the vertical nut

Control axes allow the wire to be cut and pushed forward:

• Positioning the blade

• Wire cutting

• Feeding the wire from the coil forward

Complete drive system from one place

Most of the eyeglasses produced worldwide are produced in Asia in our day. The demand in the market is for long-lasting, space-saving and easy-to-use machines. Schüssler Technik became partners with Baumüller in the development phase of the new 3D eyeglasses frame bending machine as a competent and long-term partner. It was required form the new S-514, to modernize the machine and make it suitable for Industry 4.0.Sunbsequently, the entire drive and automation system of the machine was produced by the strategic partner Baumüller in a way to be adapted ideally to each other. All important components from drive control to machine control and visualization were supplied within the Baumüller Group. The sheet metal enclosure, including the switch cabinet, was supplied through Baumüller Dravinja, the sister company of Baumüller in Slovenia, which specializes in machine housings and switch cabinet manufacturing. Baumüller additionally undertook all the engineering works of the machine.

“Baumüller supports us in all components and the entire control system. The benefit of Baumüller as a strategic supplier with a wide range is obvious: In this way, we have very little difficulty and get faster and better application.” says Matthias Carstens, director of business development and quality management department of Schüssler Technik.

An outstanding feature of Baumüller, in addition to its space-saving, compact components, is the technical know-how thereof especially in the field of development and its currently available programming tools. The b maXX 5500 servo inverter and six b maXX 3300 servo inverters control the machine’s total seven drives as one unit.

Modern visualization and worldwide service

Modern visualization of the new S-514 ensures that the user can enter all the necessary parameters to 12″ touch screen and be able to control the machine in a comfortable way. Utilization of symbols instead of language ensures worldwide utilization without need for translation. Machine control is scalable for very hard control tasks and the latest generation of powerful performance b maXX PCC-04 series, which is a versatile usable platform, is utilized.

The demand for sensitive and independent eyeglasses production in the market is high. The new 3D eyeglasses frame bending machine S-514 prepares our customers for Industry 4.0. The machine offers a digital user interface and optional remote maintenance for worldwide use.” says Dietmar Rupprecht, director of the sales and product management department of Schüssler Technik.

Remote maintenance is extremely important for Schüssler Technik to provide a fast and economical service as a manufacturer of machines. The new machine offers an optional remote control for remote maintenance by virtue of the integrated router. This is backed by Ubiquity produced through Baumüller for secure remote maintenance solution, which is one of the first software products in the field of industrial remote maintenance certified under IEC 62443-3-3 and therefore which complies with the requirements of the basic protection catalog issued through the Information Technology Security Federal Authority (BSI). Ubiquity ensures secure access to machines around the world in order to provide support during installation, commissioning and maintenance phases and in order to provide secure remote diagnosis in case of errors or malfunctions. Baumüller offers the maintenance and preventive maintenance measures thereof at the relevant location by virtue of its global service network. Thus, worldwide glasses producers can rely on the precise production of spectacle frames realized under the roof of Schüssler Technik.

Summary

S-514, the compact, digital and precision 3D eyeglasses frame bending

machine, combined with Schüssler Technik and Baumüller

together in a modernized manner, offers numerous new options

such as modern visualization and secure remote control. The advantage

of cooperating with a strategic partner and complete supplier

like Baumüller is based on its expertise with full coverage as to both

automation components and system engineering.

Author:

Rosemarie Kmitta, Press Consultant of Baumüller

Press Officer:

Stefanie Lauterbach

T: +49 (0) 911 5432 – 319

F: +49 (0) 911 5432 – 231

E: stefanie.lauterbach@baumueller.de