Commissioning, training and the quality of technical support – the determining criteria in choosing a supplier of equipment

The choice of equipment supplier is one of the most important issues in the process of upgrading and reducing the cost of cable production.

A large number of equipment manufacturers are operating on the current market. In the face of fierce com-petition, the question of how to choose from all this variety the most reliable supplier, cooperation with which will have minimal risks, becomes acute. When quality, delivery time and price are the same for most equipment suppliers, the determining factors of selection become: service, quality of technical sup-port, attitude of the supplier and time to answer various questions and requests for assistance, training, after-sales service, the ability to order equipment from the warehouse, etc., in a word, an individual approach and the desire of the equipment supplier to make the client’s life a little easier.

With 38 years of experience Gurfil has established itself as a reliable, responsible manufacturer and sup-plier of materials and equipment for the production of cable and wire products not only in Turkey, but throughout the world.

Today Gurfil focuses on reliable and easyto-use High Speed Braiding machines and Taping Machines. Gurfil equipment allows to produce different types of cable products that fully meet the constantly tighten-ing requirements of cable security.

Highly qualified Gurfil’s engineers of carry out com-missioning works, which consist not only of measures for the commissioning of equipment, but also allow to adjust the factory settings of the equipment to the specifics of production and the individual settings of the customer.

During commissioning, engineers Gurfil pay special attention to instructing operators of the customer company.

When it comes to Gurfil’s High-Speed Braiding Machines and Taping Machines, the quality of the finished product, safety at work, as well as the life of the equipment itself, depends on the ability of operators to properly maintain and care for the machines. Although Gurfil’s equipment is quite simple to maintain, our many years of experience shows that, for example, just few people know that timely diagnosis and replacement of the most rapidly wearing parts significantly prolong the life of equipment.

Gurfil’s specialists will teach all the subtleties and lit-tle secrets of handling equipment so that it lasts as long as possible without bringing any problems. Gurfil is a member of the International Wire & Machinery Association (IWMA), one of the largest and most influential in the cable industry, which was founded in 1970 with headquarters in Solihull, United Kingdom. We are proud to be part of the IWMA’s mis-sion to promote new technologies, provide quality education and increase productivity in the cable industry.

We serve our customers throughout the world with Foil – Film – Tape products together with Machinery, offering commissioning, aftersales technical service and all spare parts from its warehouse with professional service team.

Our products are divided into three main groups: 1) Machinery group including:• High Speed Vertical Braiding Machines (16 and 24 carrier) ;

• High Speed Vertical HEAVY Braiding Machine (16 and 24 carrier) ;

• High Speed Horizontal Braiding Machine (24, 32,

• High Speed Mica Taping Machine (1,2,3 Head , Pad and Spool head options) ;

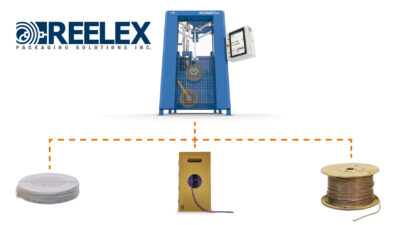

• Wire rewinding line (semi and fully automatic) with tension controlled Pay-Off;

• Pay-Off and Take-Up

• Air Wipe Units, ABS Spools.

2) Flexible Raw materials: Foil, Film and Tape Group: ALU/PET, ALU/PET/ALU, ALU/PET/SY, ALU/COPOLY Laminates;

CU/PET, CU/PET/SY Laminates;

POLYESTER FILM ;

MICA TAPE (Phlogopite, Synthetic or Muscovite) ; FOAMED PP TAPE;

KRAFT PAPER & CREPE PAPER ;

PP IDENTIFICATION TAPE ;

FIBERGLASS TAPE;

SEMI CONDUCTIVE TAPE & SWELLABLE TAPE; FLEECE, BEDDING, TNT TAPE;

NON CONDUCTIVE POLYESTER NON-WOVEN TAPE; RIP CORD YARN;

FIBERGLASS YARN;

3) Wire Group:

Aluminum Alloy Wire (0.12 mm, 0.16 mm) ;

CCA and CCS;

Skin-Foam-Skin 3 Layer Physical Foamed Conductors.

We invite you to visit our factory in Istanbul in order to learn more about our capabilities, see the equipment we offer “live”, and lay the foundation for the subse-quent fruitful mutually beneficial cooperation!